Just in

time production (JIT): the other big pilar…

It originally referred to the production of goods

to meet customer demand exactly, in time, quality and quantity, whether the

`customer’ is the final purchaser of the product or another process further

along the production line.

It has now come to mean producing with minimum

waste “Muda” ; variation “Mura” & Overburden “Muri” .

Waste ,is taken in its most general sense and

includes time and resources as well as materials. Elements of JIT include:

• Continuous improvement.

◦

Attacking

fundamental problems – anything that does not add value to the product.

◦

Devising systems

to identify problems.

◦

Striving for

simplicity – simpler systems may be easier to understand, easier to manage and

less likely to go wrong.

◦

A product oriented

layout – produces less time spent moving of materials and parts.

◦

Quality control at

source – each worker is responsible for the quality of their own output.

◦

Poka-yoke – `foolproof’

tools, methods, jigs etc. prevent mistakes

◦

Preventative

maintenance, Total productive maintenance – ensuring machinery and equipment

functions perfectly when it is required, and continually improving it.

• Eliminating waste. There are 7 types of waste:

◦

waste from

overproduction.

◦

waste of waiting

time.

◦

transportation

waste.

◦

processing waste.

◦

inventory waste.

◦

waste of motion.

◦

waste from product

defects.

• Eliminating variation. There are 3 types of

variation:

◦

Variation from

Process.

◦

Variation from Material.

◦

Variation from

Information.

• Eliminating Overburden. There are 3 types of Overburden:

◦

Overburden of Machines.

◦

Overburden of

people

◦

Overburden of

system

• Good housekeeping – workplace cleanliness and

organisation.

• Set-up time reduction – increases flexibility and

allows smaller batches. Ideal batch size is 1item. Multi-process handling – a

multi-skilled workforce has greater productivity, flexibility and job

satisfaction.

• Levelled / mixed production – to smooth the flow of

products through the factory.

• Kanbans – simple tools to `pull’ products and

components through the process.

• Jidoka (Autonomation) – providing machines with the

autonomous capability to use judgement, so workers can do more useful things

than standing watching them work.

Andon (trouble lights) – to

signal problems to initiate corrective action.

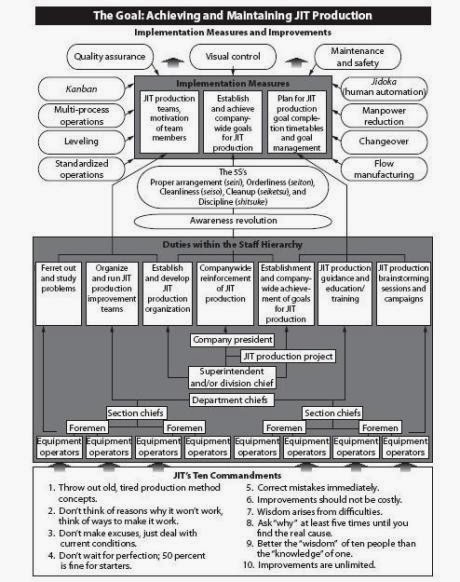

Fig.

Hence we can see that to have a Total JIT

manufacturing system, a company-wide commitment, proper materials, quality,

people and equipments must always be made available when needed. In addition;

the policies and procedures developed for an internal JIT structure

should also be extended into the company’s supplier and customer base to

establish the identification of duplication of effort and performance feedback

review to continuously reduced wastage and improve quality. By integrating the

production process; the supplier, manufacturers and customers become an

extension of the manufacturing production process instead of independently

isolated processes where in fact in clear sense these three sets of

manufacturing stages are inter-related and dependent on one another. Once

functioning as individual stages and operating accordingly in isolated

perspective; the suppliers, manufacturers and customers can no longer choose to

operate in ignorance. The rules of productivity standards have changed to shape

the economy and the markets today; every company must be receptive to changes

and be dynamically responsive to demand. In general, it can be said that there

is no such thing as a KEY in achieving a JIT success; only a LADDER;

where a series of continuous steps of dedication in doing the job right every

time is all it takes.

Fig.

No hay comentarios.:

Publicar un comentario