Heijunka Concept.

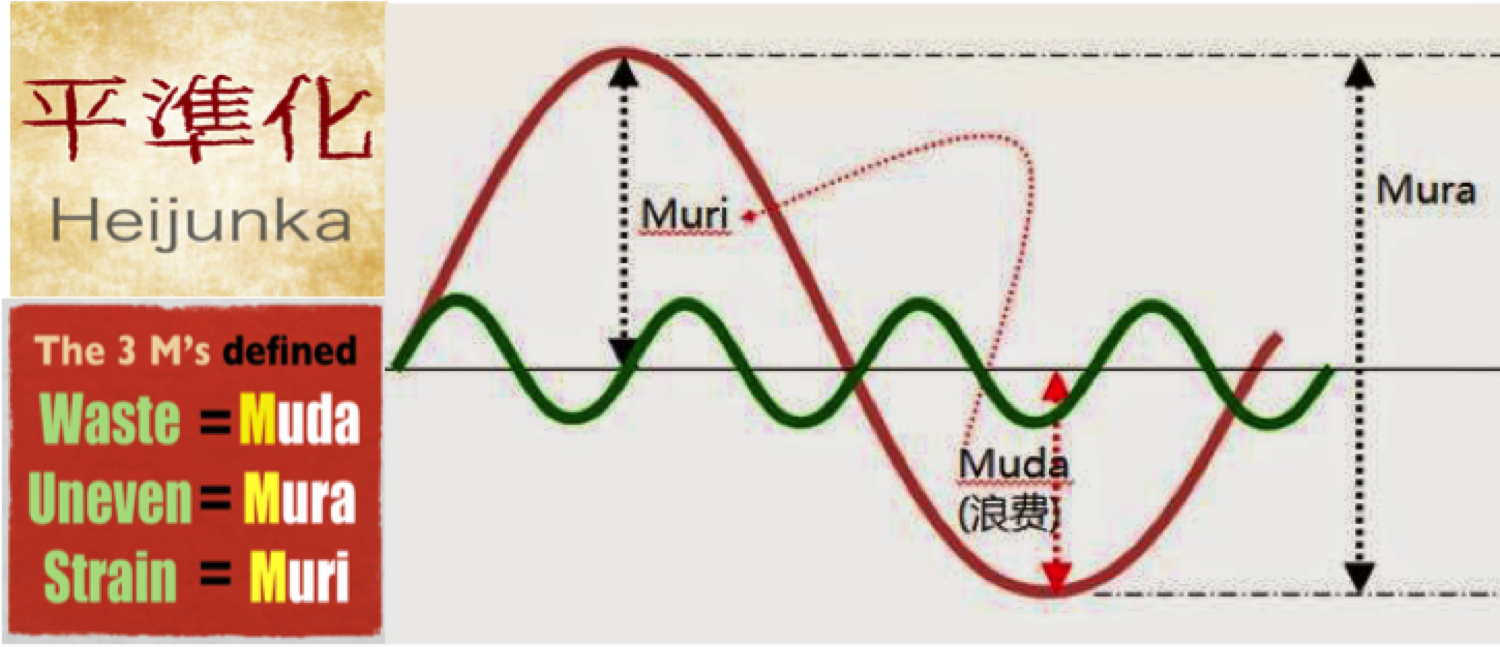

No mass production system can be continuously responsive to gyrating

orders without suffering from muri (overburden of machines, managers, and production

associates), and mura (unevenness in productivity and quality). And mura and muri together create muda

(waste).Fig.

Relationship Among Predictability, Flexibility and Stability Is Heijunka – When implemented correctly, heijunka provides predictability by leveling demand, flexibility by decreasing changeover time and stability by averaging production volume and type over the long term.

Here is how some Lean Books defines heijunka: “Leveling the type

and quantity of production over a fixed period of time. This enables production

to efficiently meet customer demands while avoiding batching and results in

minimum inventories, capital costs, manpower, and production lead time through

the whole value stream.”

From Pitch to Heijunka

Pitch is

the bridge connecting customer pack quantity with takt, so it makes no sense to

build products in less quantity than the pack size. The same is true for

creating production batches that are not multiples of the pack sizes.

Once we have Pitch we can develop a Heijunka

Box which tells the operator what to build every pitch interval.Fig.

Heijunka – The Load Leveling Box

Fig.

Develop a Heijunka Box for a days

production from the data below

Fig.

This Heijunka Box shows lot quantities to

produce per Pitch

Fig.

This Heijunka Box shows pallets to

produce per Pitch

Fig.

The information about what product to build on

the next Pitch is placed in the Heijunka box when completed products are picked

up.

Since products are picked up from the line at

the same rate as the others are scheduled for production Pitch by Pitch, any

problem with Flow will prevent pick up and become visible immediately.Fig.

The method that compiles the days production

requirement and lets the line determine the sequence is not Heijunka, but it

allows higher flexibility in a true high mix / low volume line

Kaizen the Ship Frequency

If the EPEI (or Interval) for all the

processes (pacemaker and upstream) is equal to the ship frequency, then the

entire value stream will flow

Ideal ship frequency is daily or more frequent

to the customer as this will continuously engage the pacemaker and upstream

operations to improve

Steadily increasing the ship frequencies is

therefore a highly worthy kaizen project for you and the customer.

The facility would be able to convert raw

materials into finished goods that can garner cash before the material bills

come due.

Response to change in

demand.

Rule of thumb:

• Kaizening the process can never

finish

• Customer demand always changes

• Design of pacemaker needs to

consider changing volumes

• A year-long history of shipment

may show periods of stable demand

For increasing demand:

• Smaller day-to-day fluctuations

are best handled by use of a finished goods supermarket (allows for takt time

and resource planning)

• Run a little overtime each shift

• Toggle the number of operators

(may require takt time adjustments due to change of work distribution)

Fig.

Keeping in mind the core concepts about heijunka will help keep a

company heading in the right direction.

•

Takt time: The time it takes to finish a product in order

to meet customer demand; can be thought of as the customer buying rate. It is

the guidance for the entire heijunka implementation.

•

Volume leveling: Manufacture at levels of

long-term average demand and keep a buffer inventory proportional to variability

in demand, stability of production process and shipping speed.

•

Type leveling: Essentially, make every

product every day and reserve capacity for changeover flexibility; use a heijunka

box to visualize the production flow and schedule.

•

Heijunka box: A working

diagram of type leveling and production schedule.

•

Work slowly and consistently: Taiichi Ohno,

founder of the Toyota Production System, says it best: “The slower but

consistent tortoise causes less waste and is much more desirable than the

speedy hare that races ahead and then stops occasionally to doze. The Toyota

Production System can be realized only when all the workers become tortoises.”

•

Changeover time: Efficiency of changeover is

the fulcrum of heijunka; narrowing changeover times helps tighten the

value stream between supply and demand.

•

Buffer inventory: Having some product ready

to ship at the beginning of each production cycle is essential to smoothing

production and leveling demand at consistent rates and quality so that resource

waste is minimized on the line.

Type standardization: By manufacturing one of each product or service a

day, knowledge can be more readily shared across types to benefit every

process.

Article is giving really productive information to everyone. Well done.

ResponderBorrarpart time MBA programs in Chandigarh

best institutes for btech in chandigarh

six sigma course